Rack and Stack solution: Nexpand TR - Fast to deploy in a safe, sustainable, and secure way

Olaf de Jong (Manager R&D) and Mike van der Donk (Product Manager), discuss the company’s new Nexpand TR cabinet solution, designed for shipping with equipment pre-loaded, providing several operational, financial and sustainability benefits for the customer.

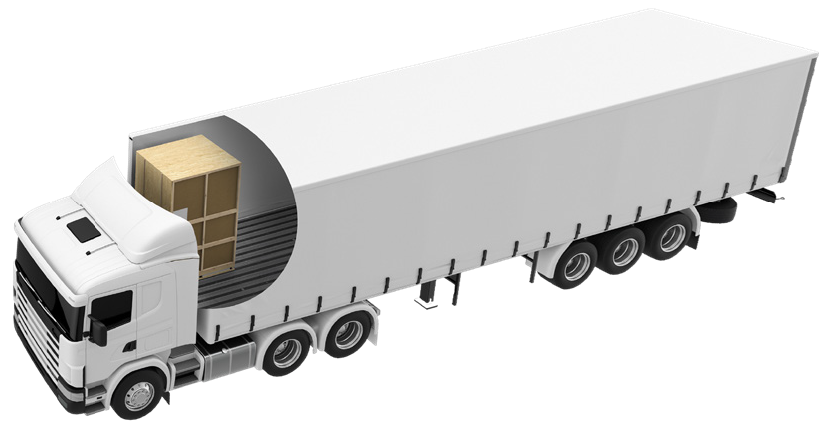

The obvious question to ask is, when you already have a wide range of standard, customisable cabinet solutions, why the need for the new Nexpand TR cabinets? Mike van der Donk explains: “The initial thought we started with was that we saw the need to accommodate more and more heavier equipment in the cabinets and we wanted to combine that with the additional value of enabling suppliers of servers and other IT equipment to pre-install it in the cabinets and then deliver it to their end customers, rather than having to go to the end customers’ sites and having to install the kit there.”

He continues: “We wanted the cabinet to support 1020 kilograms of equipment in the cabinets, so that the server supplier, for example, can install those in a safe environment in their own factory or warehouse. They have the right tools there, and they can troubleshoot easily whatever is necessary, rather than do it on the customer’s premises.”

There’s a cost-saving advantage as well, as the end customer saves significant time on the on-site install, with a corresponding reduction in the installation charge.

The main benefit of the new Nexpand TR cabinet solution, however, is the fast deployment time – in a secure way.

In order to achieve this objective, Minkels has addressed two key areas: the actual design of the new TR cabinets and the integrity and sustainability of the packaging.

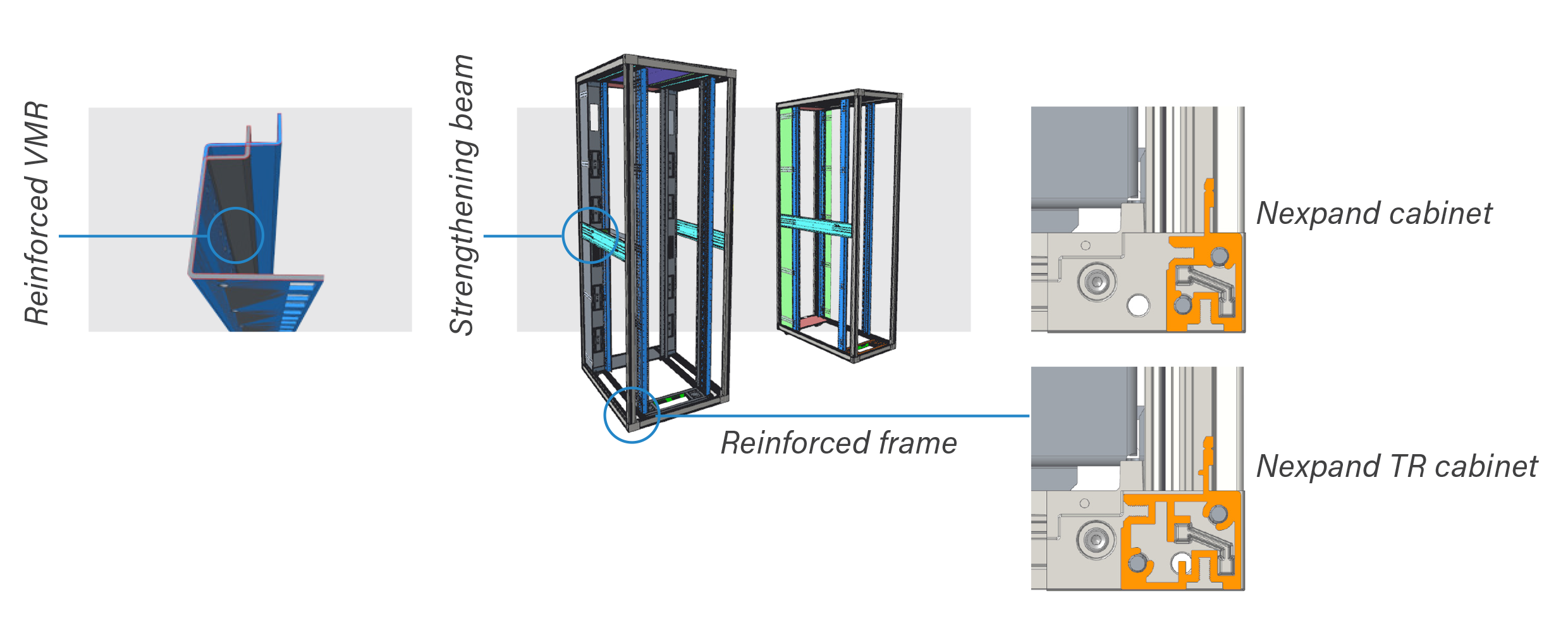

In terms of how the standard Nexpand cabinet has been strengthened, Olaf de Jong explains: “The frame is reinforced by having a reinforced height post, so that it is stronger and more rigid. There is also an additional strengthening beam that is in the depth and there’s also the VMR, so the 19 inch is reinforced. These are the three main differences compared to the Nexpand standard frame. And we’ve also added castors (which can be added to a normal frame, but these ones are capable of carrying the heavy load.”

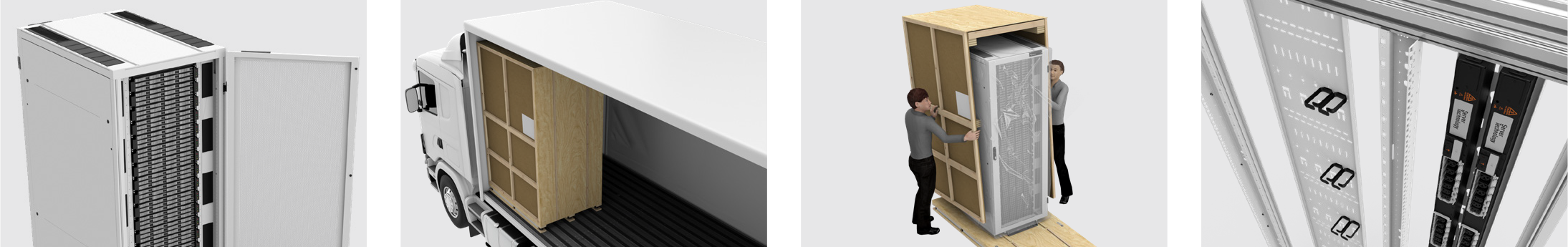

Equally crucial is the design of the reusable packaging used to transport the pre-populated cabinets to the customer’s site. Olaf takes up the story: “The packaging capabilities are tested according to International Safe Transit Association (ISTA) standards. We used the impact test to check for any damage to the contents, the stability test (to check the package will not tip over easily) and the vibration test – for vertical movement in the truck.

“With pre-populated cabinets, it’s a lot of value that’s being transported and that’s the main reason why you want excellent quality protective packaging. And, yes, there is an investment required in the packaging, but it can be re-used, if handled carefully, at least 10 times. That’s good from a sustainability perspective, but it also makes financial sense, as the lifecycle cost of our packaging solution will be less expensive than buying disposable packaging every time.”

The packaging is of flat-pack design, consisting of a pallet base, the wooden casing, and an integral ramp. No specialist tools are required to either secure the packaging prior to transportation or during the unpacking and installation phases – with the unpacking and installation manual guiding the end customer through these latter processes.

It’s also worth emphasizing that the buffering material used between the cabinet and the outer box is all made from cardboard. Additionally, the packaging is modular in design so, when any components do need repairing or replacing, there is no need to throw away the whole package.

The TR cabinets are just one more example of Minkels’ ability to listen to customers and then to deliver what they are asking for. Olaf says: “We identified many companies who were saying that they were getting heavier and heavier equipment, so they needed a more robust cabinet solution to cope with this. They were also saying that, in many cases, rather than arriving at the data center, where the cabinets are already installed, with the servers and other IT equipment, it would be much easier if they could pre-install everything at the server factory and then ship to site.”

Nexpand TR meet these requirements securely, safely, speedily, and sustainably and, furthermore, like the company’s standard cabinets, they are highly customisable. Olaf adds: “Of course we have a catalogue with standard configurations, but I really want to emphasise that we can change the design according to the customer’s needs. If they want a specific cable management solution or different doors, or integrated PDUs – we always want to have a conversation with the end customer to understand exactly what they want and to explain what we will deliver and when.”

One imagines that the new Nexpand TR will initiate many such conversations over the coming months.