CUSTOMEr CASE: Telehouse

Country: France

Deployment of a Data center in the heart of Paris, operated by Telehouse

When the leading European provider of colocation data centers creates a new high-tech facility, selecting the best manufacturers of dedicated solutions is a must. By choosing Legrand products and support, Telehouse has opted for performance, reliability and security.

Discover the full story:

The colocation and network-neutral secure data center provider Telehouse has operated in France since 1996. It oversees 3 data center facilities in Greater Paris, and one in Marseille. The company’s flagship facilities are TH2 in Paris and TH3 located in the Yvelines department. Telehouse provides hosting services in ultra-secure rooms with racks, half-racks and quarter-racks aimed at a wide range of customers (service providers, broadcasters, cloud providers, businesses, etc.). “Customers come to us for our resilient infrastructure and our rich ecosystem, explains Selma Kamel, Head of Design, Engineering & Customer Experience. We also offer high electrical and climatic availability, along with services such as racking, deracking and rebooting, as well as connectivity services. In short, all the services needed for colocation hosting and IT room layout”.

A large-scale project

The latest Telehouse data center officially opened in 2022. It is situated in the heart of a fully-refurbished office building, in which the IT rooms occupy a surface area of 4,500 m2. Boasting 5 MW of power, it hosts 1000 racks and 2000 PDUs. This latest-generation data center offers particularly high performances, reflected in its Tier 3 classification, providing maximum availability. Its target PUE is 1.35 (the average data center PUE is around 1.60), giving an indication of its highly-efficient energy usage. Given that energy efficiency is a key concern (see boxed text), an efficient cooling system has been installed. In this way, the free cooling system allows the cooling units to take a break in the winter season, and an adiabatic system helps optimise their output in the summer. The heat released by the servers is reinjected into the urban grid to heat surrounding residential and commercial properties. On this site, Telehouse has also opted for rooms with raised flooring and a hot corridor/cold corridor layout. The choice of a cold corridor primarily addressed an essential need for containment in order to prevent hot and cold air flows from mixing. Ultimately, this option helps optimise the data center’s energy efficiency and improve working conditions for customers.

Dedicated colocation solutions

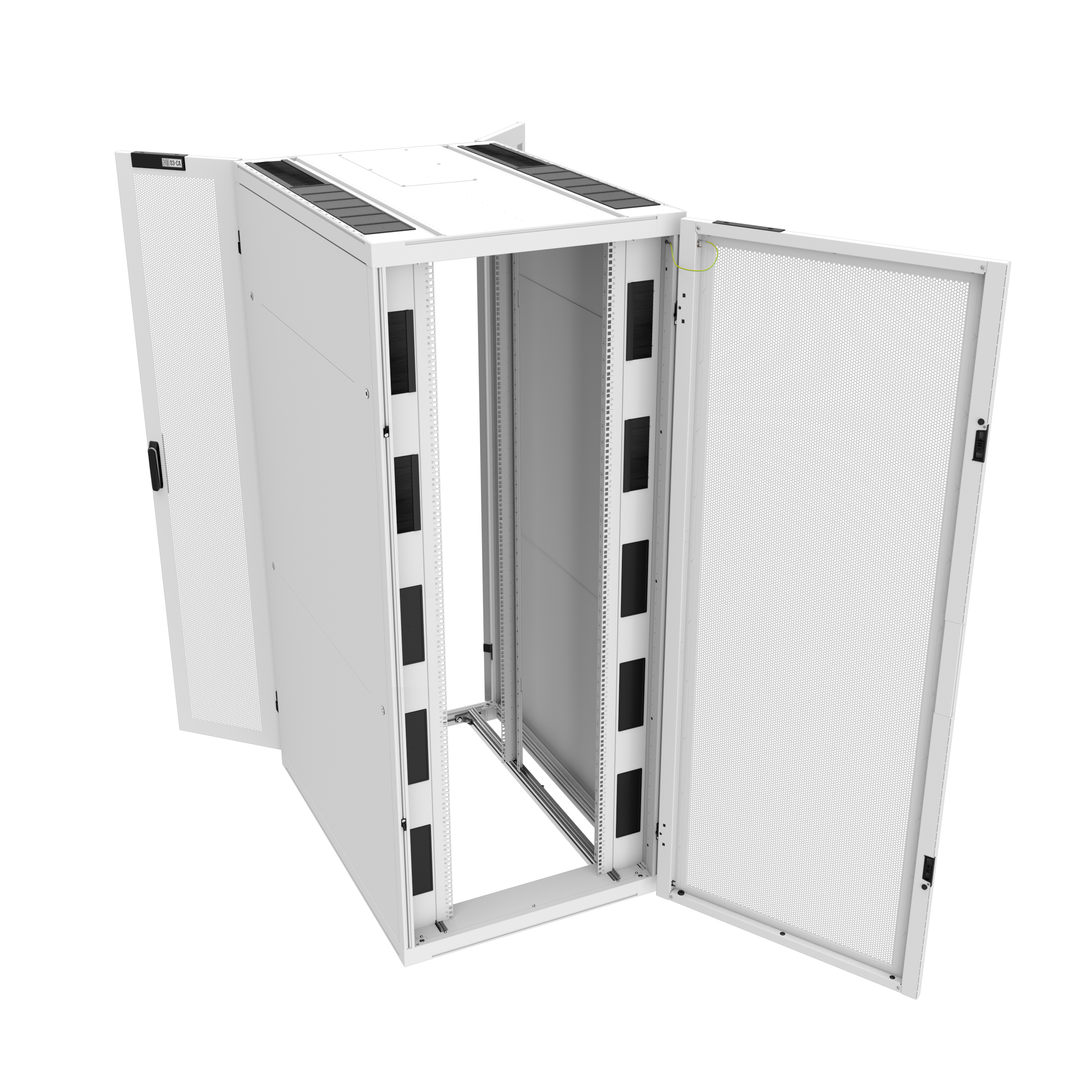

Telehouse selected Legrand products to fit the Léon Frot facility out with racks, cold corridors and PDUs. For Selma Kamel, this was the obvious choice. “We were already well acquainted with Legrand as we had been using their solutions for years. Following a tender process involving five competing manufacturers, we selected them based on technical, financial, CSR and logistical criteria. We were also keen to use a European group – it is important for Telehouse to support digital sovereignty in France. We specifically opted for Minkels racks, as we were looking for heavy-duty racks that were infinitely configurable according to customer profiles. For example, 52 U racks, which can be split into quarter- or half-racks. The compartments are also very secure with dedicated cabling compartments. These racks are very well suited to colocation and are popular with our customers. Our facility was also faced with a design constraint which led us to choose a water mist fire extinguishing system. With their FM Global-certified Drop Away roof panels, Minkels cold corridors are perfectly suited for our extinguishing system”. Finally, in terms of security, Legrand offers all types of security systems: badge reader, biometrics, key or code lock, etc., meeting the most stringent standards stipulated by Telehouse and its customers.

Marc Daoud, Sales Manager at Legrand Data Center Solutions, was tasked with following up the Léon Frot project. He talks about the challenges in this project and the solutions that Legrand came up with.

How did the Minkels solution deployment process go, given the need to account for the facility’s inherent constraints and customer requirements?

Marc Daoud: We received a large order from Telehouse to deploy approximately 400 racks and a sizable number of PDUs. They made one-off containment requests, as their customers did not all have the same requirements. Some wanted to combine two rows of five racks placed in a cage, and others asked for the containment of two rows of fifteen racks with a large corridor, etc. As the deployments progressed, we received 2D drawings giving us indications of containment lengths, as well as the position of the posts located in the room. Each time, we had to come up with a cold corridor design and a precise quotation. We then progressively delivered as the customers moved in. Given the specific constraints and requests, we systematically worked on custom solutions and operated in project mode.

What type of organisation did you set up at Legrand to carry out this project?

Marc Daoud: In-house, we worked in a team of three. Besides myself, one person was in charge of incoming calls, orders, planning deliveries, managing any delays, as well as scheduling access to the site for our teams. We also had a project manager who was tasked with handling orders, acting as an interface with the factory when we needed custom solutions, and managing subcontractor teams assigned to assembling the racks. His duties also included supervising installation. We also communicated with the various project managers working in our factories.

Why would you describe this project with Telehouse as a collaboration?

Marc Daoud: Our collaboration is not new, Legrand has actually been working with Telehouse for over ten years. In terms of this particular deployment, our collaboration was underlined with constant communication in difficult circumstances and great transparency between us. When either party encountered a problem, we discussed it and we came up with the right solution together to handle the situation. We also helped each other out at critical points with equipment supplies. Throughout the project, we worked hard at both ends to keep our relationship strong; that is why we have been working together for so long.